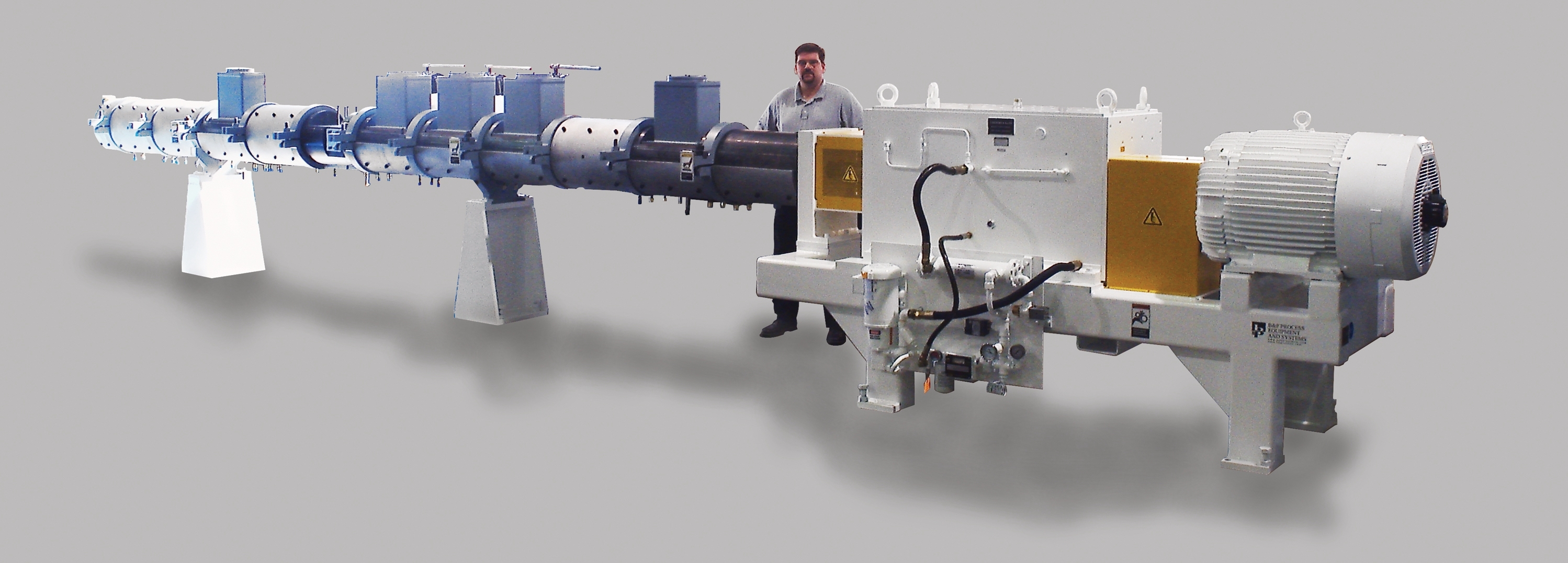

Specialty Twin Screw

B&P Littleford’s Specialty series extruders allow for excellent mixing, optimal degassing, and reliable cooling with high throughput. These extruders feature robust machine construction that has low maintenance requirements, and modular construction for enhanced process flexibility.

B&P Littleford’s decades of experience in mixing, outstanding engineering, and construction skills come to the forefront in execution of its Specialty series extruders. This technology is setting new standards in melt devolatilization, and in the manufacture of various polymers, compounds and chemicals.

John C. Vaaler Award Recipient

The largest twin-screw reactor to be built anywhere in the world to date was shipped from our Saginaw, Michigan factory in 1969. One of two MP-Series specialty extruders built for one of the world’s largest chemical companies, the twin stainless steel screws were 889 mm in diameter (35”)! Saginaw received the John C. Vaaler Award from Chemical Processing magazine for this achievement and it was the second time in two years that Saginaw had been bestowed this Award.

Advantages

Polymers produced by synthesis contain volatile residual monomers that can have a negative environmental impact and an adverse effect on the functional properties of the polymers. Our specialty series extruders have proven themselves to be effective for degassing higher molecular residual monomers from polymer melts. They provide for high product quality and improve the functional properties.

Stripping agents, stabilization additives and/or catalysts for cross-linking can be homogenously mixed in using various additive inlet ports along the length of the extruder. Compared to other mixing machines, the specialty series twin screws offer a critical advantage and substantial competitive edge by means of efficient pumping output using the patented XLT discharge.

Our Expertise

With years of experience from numerous projects, tests, simulations, and scale-ups, our process specialists adapt the extruder optimally to your mixing or devolatilization application, from the lab-scale extruder to the high-performance compounding plant. Contact us for more information on how your product would run through this equipment.