Continuous Kneader

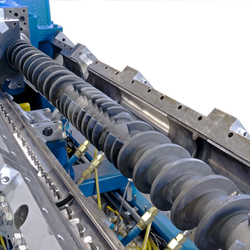

The B&P Littleford Continuous Kneader is a moderate-shear rotating and reciprocating single-screw extruder ideally suited for shear- and temperature-sensitive compounds. The flights on the screw are interrupted and interact with three rows of stationary kneading pins located in the barrel wall. The interaction between the moving flights and the stationary pins provide dispersive mixing and distributive mixing simultaneously.

Pressurization and discharge shaping of the output from Continuous Kneaders is executed by utilizing a separate metering device such as a melt pump or a single-screw discharge extruder. The inherent separation of the kneading step from melt pressurization step results in greater process flexibility (i.e. a wider processing window), improves mechanical energy efficiency (efficient mixing at high screw speed combined with efficient pumping at lower metering speed) and lowers the overall melt temperature.

Our Continuous Kneader Portfolio

B&P Littleford’s comprehensive Continuous Kneader portfolio provides the most suitable solution for the mixing and extrusion of plastics and other basic materials, and largely out of our standard product offering.

- Continuous Kneaders available in a wide range of screw sizes from 30-300 mm with process lengths ranging from 8 to 20 L/D.

- Compact high-performance gearbox, capable of screw speeds up to 750 rpm.

- Cored screw shaft option for fluid tempering.

- Electric heating and water cooling (standard) or fluid cooling (optional).

- Wide range of customized supporting equipment such as top feeders, side feeders, vacuum vent stuffers, vacuum connection chute, melt pump, discharge extruders and die face pelletizer.

Process Control System

B&P Littleford’s process control system provides visualization functions to regulate and monitor the process in real time. The system is a clearly arranged touch display and membrane keyboard that allows for:

- Failsafe interlocking

- Large view of selectable running data using trends representation

- Fault message system with visual representation and archiving

- Convenient operating help in clear text

- Graphic and tabular representation

- Multi-step login

- Language change-over

- Recipe management of all process parameters

Advantages of Continuous Kneaders

Process advantages of the B&:0;P continuous kneader include:0;

- Peak shear rate is lower than other compounders

- The continuous kneader operates at comparatively lower internal pressure

- Excellent distributive mixing eliminates localized scorching that may be generated in the shear gap

- Uniform shear and elongation:0; Applications

B&:0;P Littleford Continuous Kneaders are well-proven in applications requiring gentle kneading, dispersive mixing and distributive mixing. They have a very successful track record in processing:0;for more information on how your materials would process through a Continuous Kneader from B&:0;P Littleford.

:0